Dec 29,2025

By:

Introduction

The chlor-alkali industry plays a critical role in the global chemical value chain, supplying essential products such as chlorine, sodium hydroxide (caustic soda), and hydrogen. These chemicals are widely used in water treatment, PVC manufacturing, pharmaceuticals, pulp and paper, and many other industries.

Modern chlor-alkali plants are designed to improve energy efficiency, product purity, and environmental performance, with membrane cell technology becoming the industry standard.

What Is a Chlor-Alkali Plant?

A chlor-alkali plant is an industrial facility that produces chlorine, sodium hydroxide, and hydrogen through the electrolysis of sodium chloride brine. The plant consists of brine preparation systems, electrolytic cells, product separation units, and downstream processing equipment.

With increasing environmental regulations and energy costs, chlor-alkali plants worldwide are transitioning from traditional mercury and diaphragm technologies to advanced membrane cell systems.

The Chlor-Alkali Process Explained

The chlor-alkali process involves the electrochemical decomposition of purified brine using direct current electricity.

Key Chemical Reactions

At the anode:

Chloride ions are oxidized to produce chlorine gas.

At the cathode:

Water is reduced to generate hydrogen gas and hydroxide ions.

In solution:

Sodium ions combine with hydroxide ions to form sodium hydroxide.

Main Cell Technologies

Mercury cell – largely phased out due to environmental risks

Diaphragm cell – moderate efficiency, lower product purity

Membrane cell – high efficiency, high purity, environmentally friendly

Advantages of Membrane Cell Technology

Membrane cell technology has become the preferred solution for new and upgraded chlor-alkali plants due to its clear technical and environmental benefits.

1. Lower Energy Consumption

Membrane cells require significantly less electrical energy per ton of sodium hydroxide produced, resulting in lower operating costs and reduced carbon emissions.

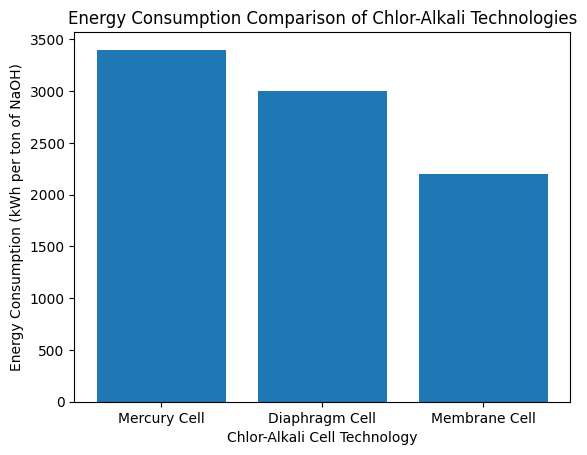

Figure 1. Energy Consumption Comparison of Chlor-Alkali Technologies

This chart compares the electricity consumption of mercury cell, diaphragm cell, and membrane cell technologies. Membrane cell technology demonstrates the lowest energy consumption per ton of sodium hydroxide, highlighting its superior energy efficiency.

2. Higher Product Purity

The ion-exchange membrane selectively allows sodium ions to pass while preventing chloride ion migration. This results in:

Higher purity caustic soda

Reduced downstream purification requirements

Improved product consistency

3. Environmental and Regulatory Compliance

Unlike mercury and diaphragm cells, membrane technology does not use toxic substances such as mercury or asbestos. This makes membrane-based chlor-alkali plants:

Environmentally sustainable

Safer for plant personnel

Fully compliant with modern environmental regulations

4. Operational Reliability and Safety

Membrane cell systems offer:

Stable long-term operation

Lower maintenance requirements

Reduced risk of product contamination

Future Trends in Chlor-Alkali Production

The chlor-alkali industry continues to evolve in response to sustainability goals, digitalization, and market demand.

1. Global Shift Toward Membrane Technology

Membrane cells are expected to dominate global chlor-alkali capacity as older plants are upgraded or decommissioned.

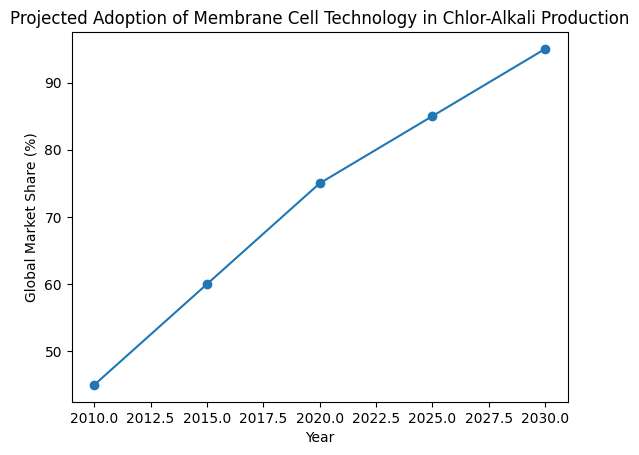

Figure 2. Projected Adoption of Membrane Cell Technology in Chlor-Alkali Production

The chart illustrates the increasing global adoption of membrane cell technology, driven by stricter environmental regulations, rising energy costs, and sustainability targets.

2. Advanced Membrane Materials

Ongoing research focuses on:

Longer membrane lifespan

Higher chemical resistance

Reduced electrical resistance

These innovations will further improve efficiency and reduce operational costs.

3. Integration of Renewable Energy

As the chlor-alkali process is electricity-intensive, many producers are exploring integration with renewable energy sources such as solar and wind power to reduce carbon footprints.

4. Digitalization and Smart Chlor-Alkali Plants

Automation, real-time monitoring, and AI-based process optimization are becoming key trends, enabling:

Higher production efficiency

Predictive maintenance

Enhanced operational safety

Conclusion

The chlor-alkali industry remains a cornerstone of modern chemical manufacturing. As environmental regulations tighten and energy efficiency becomes increasingly important, membrane cell technology is shaping the future of chlor-alkali plants worldwide. With lower energy consumption, higher product purity, and superior environmental perfromance, membrane-based chlor-alkali production represents a sustainable and economically attractive solution for the industry's. As an experienced engineering company in the chlor-alkali field (caustic soda field), BPC is committed to providing upgrading services for chlor-alkali clients worldwide.

Hi! Welcome back.

How are you doing?

BPC is the leader of China for overseas chlor-alkaili marketing and sales business, as well as an engnieering company to provide chlor-alkali process and caustic soda plant service for global clients.

+86-10-67711588

Room 401-1, No. 20 Kechuang 14th Street, BDA, Beijing, China